HDX-MS (hdx mass spec) a valuable tool for characterization of proteins and peptides.

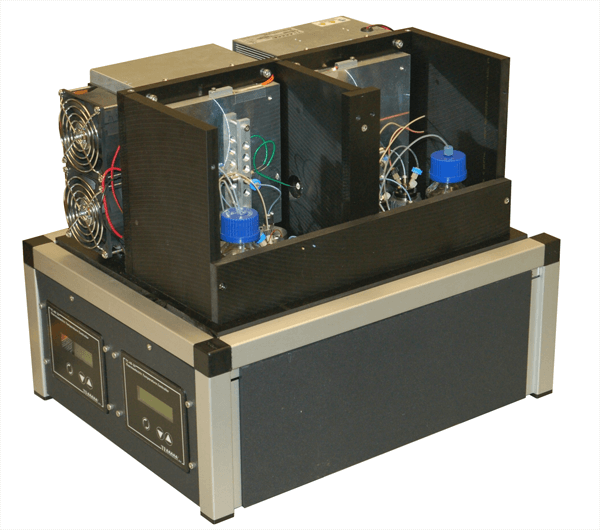

An affordable automated Hydrogen Deuterium Exchange (with mass spectrometry component HDX-MS) solution for the budget conscious lab. Label, quench, digest and separate all in one convenient package and all in-line. Two thermo electric cooler zones - one for labeling and one for quenching. HPLC pump heads replace typical syringe pumps for plenty of pressure. Quick reaction times - under 1 second. Software control gives the user easy control over experimental conditions. A perfect product for the university Core Lab or start up, delivered by CSS Analytical and priced at under $50k.

Theory of Operation

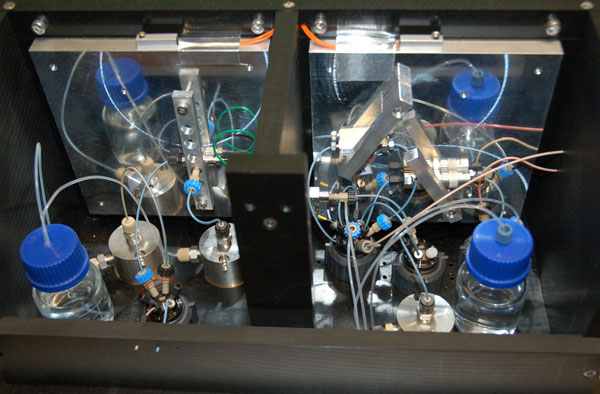

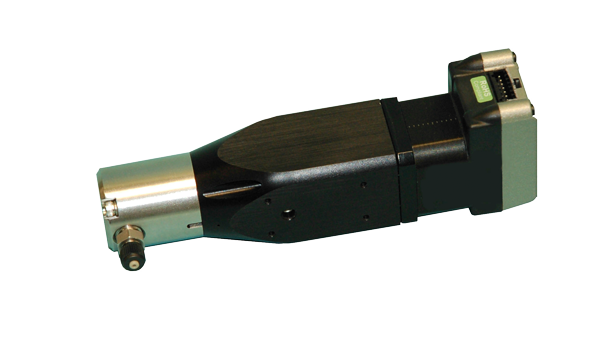

The system consists of two independently chilled chambers. Within the coolers are 4 HPLC valves, 3 HPLC pump heads (and solvent reservoirs), two mixing tees, a trap, pepsin column and analytical column. A line comes in to the analytical valve from your binary pumping system and a line exits the cooler from the analytical column to your mass spec.

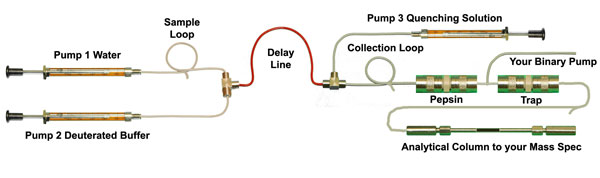

A simplified system diagram is shown below. What makes this a simplified diagram is that we left out the four HPLC valves that change the flow path. HPLC pumps are depicted as syringes.

Sample is loaded onto a loop, the sample valve switches and the sample and D2 buffer are pushed into a mixing tee at a dilution rate specified by the user. After mixing, the buffered sample passes through the delay line for a defined amount of time, "experimental time". This time determines the amount of exchange or labeling. Quenching occurs at the quenching tee and then the sample is collected on the collection loop. The sample prep valve switches and the sample is pushed off the collection loop by the same quenching solution and passes through the pepsin column and onto the trap (to waste). The sample prep valve switches back and the trap is washed by your binary pump to waste instead of the mass spec. The analytical valve is switched, a contact closure starts your mass spec and the gradient program on your binary pumping system begins. And finally, the trapped and cleaned sample is pushed off the trap by your binary pump, with your programmed solvent gradient and onto and through the analytical column to your mass spec.

Hardware Description

System hardware consists of two chambers with independently controlled thermo-electric chillers capable of maintaining the enclosures and contents to zero degrees centigrade. Three HPLC pumps and four HPLC valves (6 port, 10 port, 6 port, 6 port). A Pepsin column, Trap and Analytical column are provided by the customer. Contact closure for remote start of your mass spectrometer is included. All coolers, pumps, valves and contacts are controlled by custom software and a simple user interface. The boxes require 18” x 14” of bench space. A power supply require additional space under the bench. The software can be loaded onto your mass spec PC or onto a separate PC so that the unit can be mobile and used on different mass specs. A custom cart with multiple shelves is ideal but not included.

Software Description

The software interface amounts to one compiled program consisting of three “tabs”, or pages.

The Configure Tab is where the user sets up the system with various system variables like the sample loop and collection loop volumes and the length and diameter of the delay line. Other constants like mass spec run time and the specifics on purging the system are entered here as well.

The Manual Control Tab is where the user has complete control of all three pumps and four valves. The pumps are “homed”, flushed and filled using this page in order to get ready for a run or series of runs.

The Run Control Tab is where the experimental variables are entered like the two dillution factors and the age of the reaction or labeling time. The “calculated” variables, i.e. pump flow rate, pumping and valve switching times are calculated and displayed. The experimental run is started and the status is monitored on this page.

The software is customizable to user preferences. k